Downtime/Reliability

Downtime/Reliability

Reliability, also known as downtime tracking, is crucial for maintaining continuous production and minimizing unscheduled downtimes. manuFACT™ is accurate, automated, and unbiased. Every stop. Every second. Every detail.

Many companies are astonished to discover the true extent of their equipment downtime. Even if you’re unaware, downtime is happening. And once production time is lost, it’s gone for good.

Many companies are astonished to discover the true extent of their equipment downtime. Even if you’re unaware, downtime is happening. And once production time is lost, it’s gone for good.

Key Features

Downtime Tracking

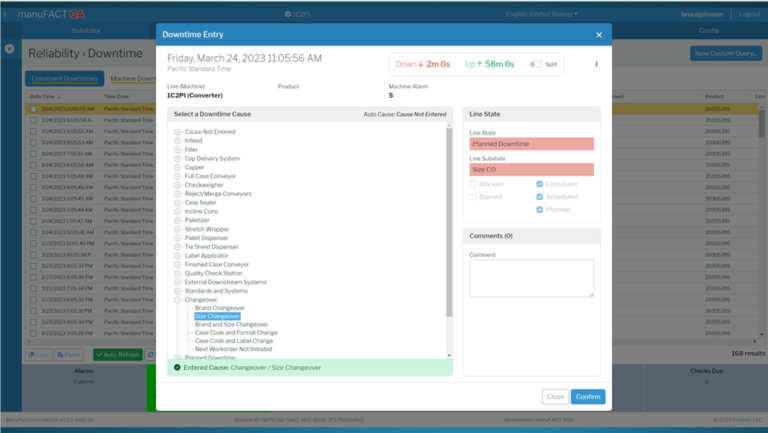

Monitor scheduled statuses (Unplanned, Planned & Idle Downtime)

Detailed logging of downtime events with reasons and durations

Analysis of downtime patterns to implement preventive measures

Detailed logging of downtime events with reasons and durations

Analysis of downtime patterns to implement preventive measures

Availability Insights

Track blocked and starved events in real-time

Real-time tracking of machine uptime and downtime

Quick identification of maintenance needs and unscheduled downtimes

Real-time tracking of machine uptime and downtime

Quick identification of maintenance needs and unscheduled downtimes

Benefits

Reduced Downtime

Efficient scheduling and maintenance through availability tracking

Minimization of unscheduled downtimes and improved machine reliability

Minimization of unscheduled downtimes and improved machine reliability

Cost Savings

Lower production costs due to improved efficiency and reduced waste

Higher return on investment with optimized resource utilization

Higher return on investment with optimized resource utilization

User Empowerment

Empower operators and managers with actionable insights

Foster a data-driven culture for continuous improvement

Foster a data-driven culture for continuous improvement

Visual Components

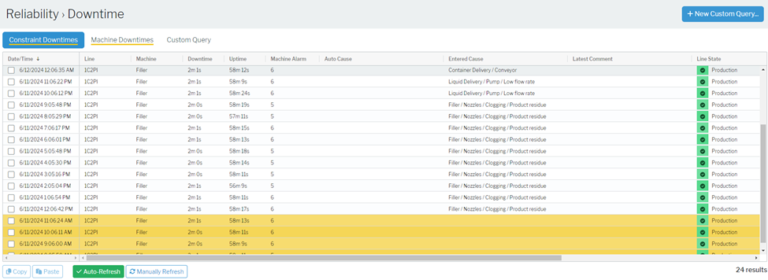

Downtime Logs

tailed visual representation of downtime events, including reasons and durations

Historical data analysis to identify and mitigate frequent downtime causes

Historical data analysis to identify and mitigate frequent downtime causes

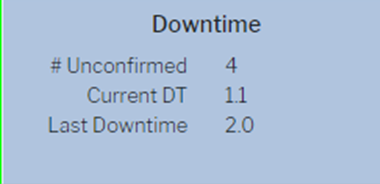

Availability Status

Real-time machine availability and downtime logs

Quick identification of maintenance needs and unscheduled downtimes

Quick identification of maintenance needs and unscheduled downtimes