Streamline Your Manufacturing

Operations with Our

Advanced MES Solutions

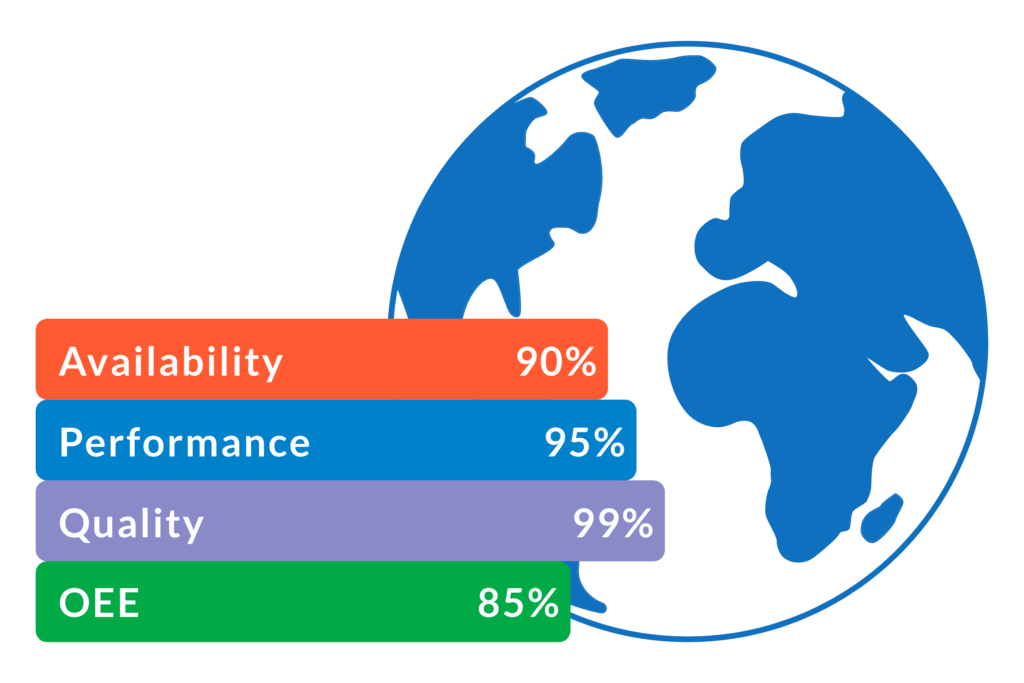

It provides powerful tools and key performance indicators (KPIs) that are used as the primary decision making resource for companies to increase efficiency and decrease downtime in their manufacturing operations around the world.

The manuFACT™ system can connect multiple plants, sites and live production information, and integrate with equipment, controllers and enterprise business applications. The result is visibility, control and optimization of production and processes across the enterprise.

Key Features

- Automated capture and tracking of equipment downtimes and production

- Highly configurable and adaptable to a multitude of operations

- Automatic determination of production losses

- OEE key performance indicators (KPI) dashboard and ad-hoc reporting

- Integration with applications and equipment throughout the enterprise

- Standard web-based reporting package with automated/scheduled reports including scorecards and KPIs

FACT: Future-Proof Your Factory

Equip your factory with cutting-edge MES technology, built to adapt and evolve with your business’s needs.

FACT: Manage Performance Across Plants

Track performance at multiple sites with our centralized dashboard, giving you total visibility and control over operations.

FACT: Scalable MES for Any Size Operation

Whether managing a single plant or a global enterprise, manuFACT scales to meet the demands of your production environment.

FACT: Automate Production Scheduling with Ease

Streamline your manufacturing operations with our automated task scheduler, eliminating human error and optimizing production timelines.

FACT: Reporting for Actionable Insights

Our system generates in-depth reports that convert raw data into actionable insights, helping you make informed decisions to drive efficiency.

FACT: Increase Operator Efficiency by 20%

Equip your team with real-time data and process alerts to maximize efficiency and reduce manual interventions.

FACT: 50% Faster Troubleshooting with DTV

Watch downtime video footage and identify exact causes in real time, reducing time to troubleshoot and resolve operational issues.

FACT: 24/7 Access via Cloud Solutions

Monitor, control, and optimize your manufacturing processes from anywhere with our cloud-based solution that provides full-time access to your production data.

FACT: Full System Integration Across Platforms

Seamlessly integrate manuFACT with existing systems and hardware, ensuring smooth data flow and efficient operations without costly overhauls.

FACT: Customizable Alerts for Any Event

Our advanced alerting module can notify you of any event or condition across your system, ensuring you’re always in control. Whether it’s a machine fault or production target reached, you’re instantly informed.

FACT: Predictive Maintenance to Prevent Disruptions

Spot potential failures and fix issues before they lead to downtime, keeping your equipment running smoothly and efficiently.

FACT: Real-Time Monitoring for Maximum Visibility

Gain instant access to production data, giving you the ability to track performance and spot issues before they escalate.

Benefits

- Make fact-based operational and strategic decision

- Continuously improve product quality and new product design

- Gain real-time visibility and control across the manufacturing supply chai$

- 24/7 support hotline for timely assistance with mission critical operation

- Accelerate trace analysis, root cause diagnosis and issue resolution

- Increase productivity, reduce waste and optimize headcount

Procter & Gamble

Request a demo

Empower Your Manufacturing with

Unmatched Reporting

run your manufacturing lines efficiently