Downtime Viewer

Downtime Viewer

The Downtime Viewer (DTV) module in Fortech’s manuFACT™ suite is a cutting-edge, web-based system designed to quickly identify and analyze the root causes of unplanned equipment downtime. This in-house developed solution integrates seamlessly with advanced camera and recording technology, allowing for rapid and precise troubleshooting.

Key Features

Real-Time Monitoring: DTV continuously tracks and displays downtime events as they occur, providing immediate insights into production interruptions. Operators and managers can respond swiftly to minimize the duration and impact of these events.

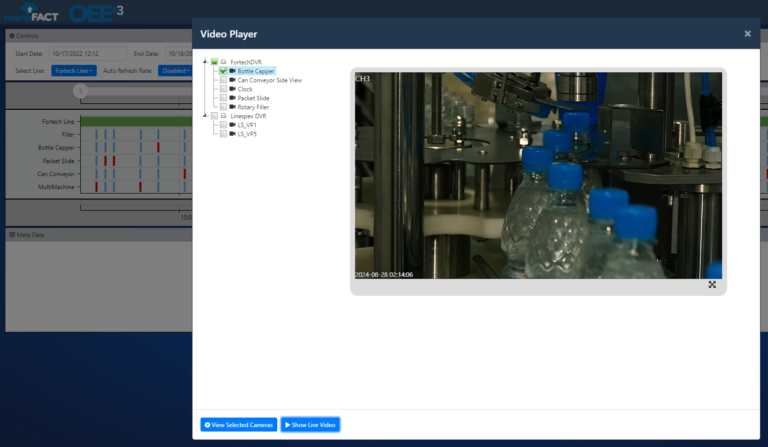

Video Integration for Root Cause Analysis: With the integration of a camera system, DTV not only captures downtime data but also records video footage of the events. This feature allows you to watch and review what happened during downtime, offering a powerful tool for diagnosing and resolving issues more effectively.

Seamless Multi-Plant Connectivity: DTV connects effortlessly across multiple plants and sites, consolidating live production data from various sources. This connectivity ensures that your entire enterprise benefits from enhanced visibility and control over production processes.

Visual Dashboards: DTV’s intuitive visual dashboards provide a clear, at-a-glance overview of downtime across your production facilities. These dashboards make critical information accessible to everyone, from operators on the plant floor to executives in the boardroom.

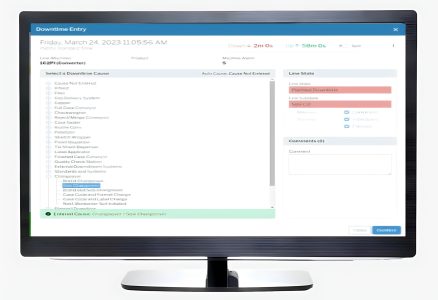

Downtime Categorization: The module categorizes downtime events, such as mechanical failures, material shortages, or operator errors. This categorization aids in prioritizing maintenance efforts and process improvements, focusing on the most critical areas.

Video Integration for Root Cause Analysis: With the integration of a camera system, DTV not only captures downtime data but also records video footage of the events. This feature allows you to watch and review what happened during downtime, offering a powerful tool for diagnosing and resolving issues more effectively.

Seamless Multi-Plant Connectivity: DTV connects effortlessly across multiple plants and sites, consolidating live production data from various sources. This connectivity ensures that your entire enterprise benefits from enhanced visibility and control over production processes.

Visual Dashboards: DTV’s intuitive visual dashboards provide a clear, at-a-glance overview of downtime across your production facilities. These dashboards make critical information accessible to everyone, from operators on the plant floor to executives in the boardroom.

Downtime Categorization: The module categorizes downtime events, such as mechanical failures, material shortages, or operator errors. This categorization aids in prioritizing maintenance efforts and process improvements, focusing on the most critical areas.

Comprehensive Equipment and System Interface: The Downtime Viewer interfaces with a wide range of equipment, controllers, and enterprise-level applications, delivering a holistic view of your production environment. This integration enables more informed decision-making and better overall equipment effectiveness (OEE).

Customizable Reporting and Analysis: DTV offers customizable reports and detailed analysis, which can be tailored to your specific needs. These reports help you track trends, compare performance across shifts or plants, and measure the success of your continuous improvement initiatives.

Customizable Reporting and Analysis: DTV offers customizable reports and detailed analysis, which can be tailored to your specific needs. These reports help you track trends, compare performance across shifts or plants, and measure the success of your continuous improvement initiatives.

Benefits

Enhanced Troubleshooting: The integration of video footage with downtime data provides a unique and powerful tool for troubleshooting. You can visually confirm the cause of downtime events, leading to faster and more accurate resolutions.

Increased Uptime: By identifying and addressing the root causes of downtime, DTV helps you maximize production uptime, improving overall productivity and reducing operational costs.

Improved Operational Efficiency: DTV’s comprehensive analysis and reporting tools support continuous improvement efforts, leading to streamlined operations and enhanced efficiency across your entire enterprise.

Cost Reduction: With better visibility into downtime causes, you can reduce maintenance costs, minimize waste, and optimize resource utilization, leading to significant cost savings.

Increased Uptime: By identifying and addressing the root causes of downtime, DTV helps you maximize production uptime, improving overall productivity and reducing operational costs.

Improved Operational Efficiency: DTV’s comprehensive analysis and reporting tools support continuous improvement efforts, leading to streamlined operations and enhanced efficiency across your entire enterprise.

Cost Reduction: With better visibility into downtime causes, you can reduce maintenance costs, minimize waste, and optimize resource utilization, leading to significant cost savings.